Across the military, as of 2013, it was found that the US Military Departments’ aggregated demand was for approximately 2,330 Ag-Zn batteries required for various subsystems through to 2017.

Keep in mind that the batteries all varied in size and complexity and this is for but one type of silver battery chemistry, Silver-Zinc.

The concern for the military industrial complex (MIC) is the limited vendors that can produce silver batteries. There remains only one domestic producer, EaglePicher, and only a handful of international options.

As of 2006, EaglePicher claimed to have produced in excess of five million five hundred thousand (5,500,000) Silver Zinc batteries encompassing over six hundred fifty (650) different configurations.

During the 1980s, the MIC underwent a transition away from silver-zinc batteries as a necessity due to supply issues.

This was in large part due to new investor enthusiasm for silver thanks in full to the Hunt Brother's squeeze which put a strain on sourcing silver at the time for military demand. Systems and applications that could be swapped to alternative battery chemistries, were.

The MIC acknowledged in the same 2013 report that if silver-zinc battery sales declined or they are not able to be produced due to supply issues, the risk that EaglePicher has as a company would be high and so the military is engaged within the silver industry to maintain AgZn battery availability into 2030.

Global Military Battery Industry

The global military batteries industry is growing due to efforts to modernize. There is rising demand for advanced, high-powered batteries in defense applications like drones, vehicles, munitions and systems.

According to TechSci Research's report, "Military Battery Market – Global Industry Size, Share, Trends, Competition Forecast & Opportunities, 2029F", the global military battery market reached USD 4.54 billion in 2023.

The report expects the market to reach 6.84 billion by 2029.

The United States, Japan, and the United Kingdom are key contributors to market growth.

The defense sector has seen an overhaul in recent years, with increasing reliance on advanced electronic systems to enhance effectiveness. Batteries play a critical role in powering defense equipment, ranging from communication devices to unmanned vehicles and precision guided munitions.

Silver's strength as a strategic metal shines in aerospace and naval warfare domains due to the extreme conditions of these environments and high energy demand of modern high tech weapons.

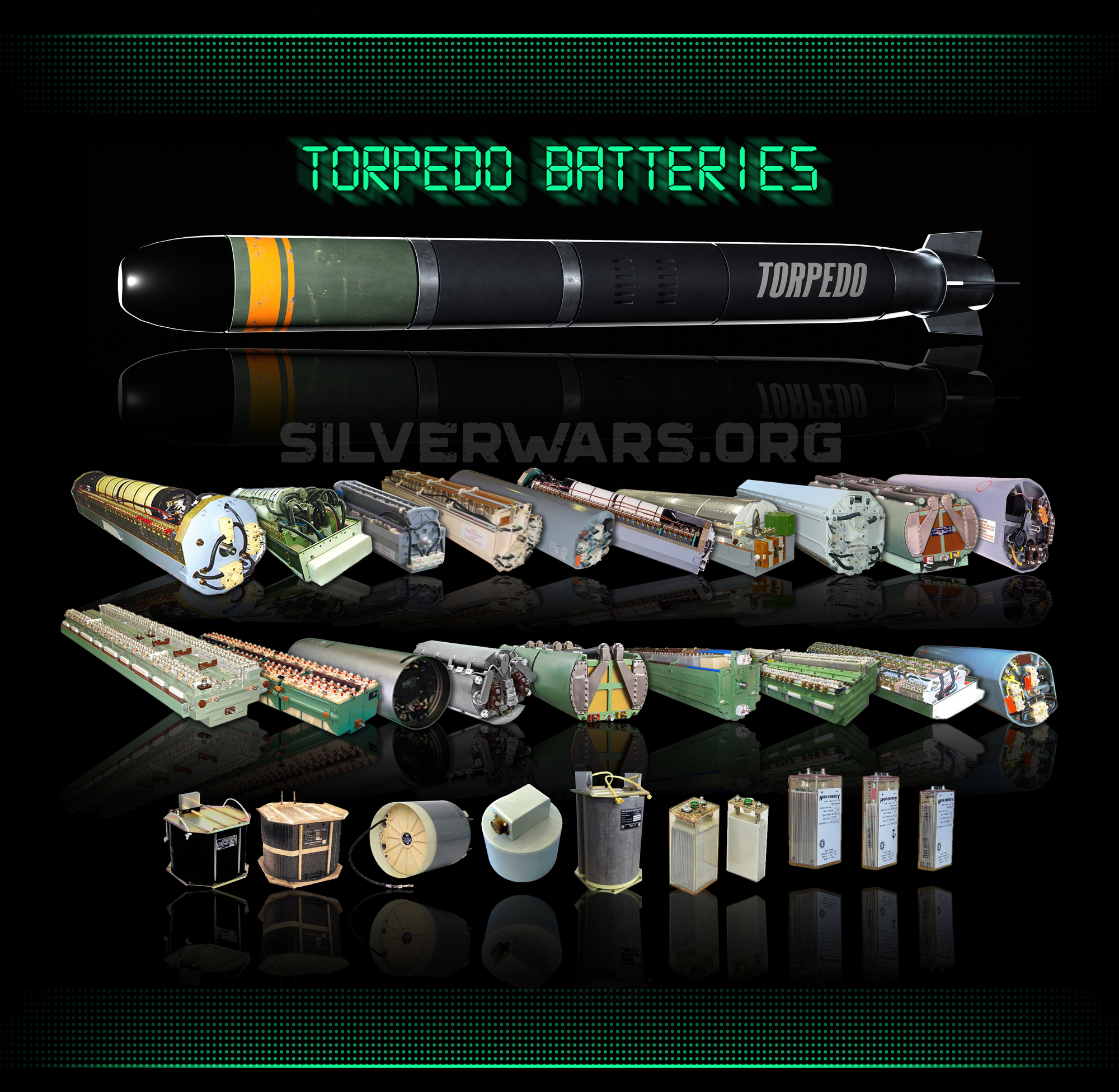

Sea Water Activated Batteries

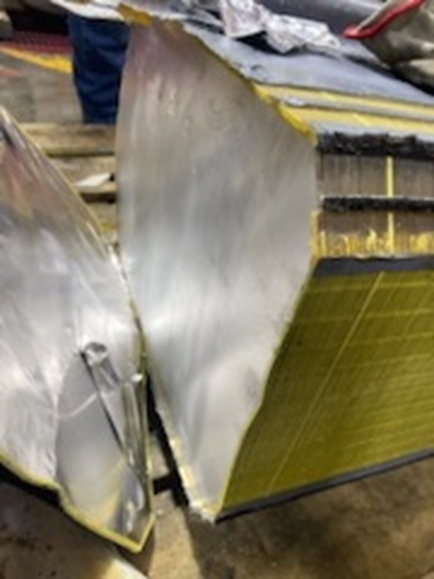

Its difficult to determine the exact amount of silver found in various munition batteries due to national security, but in the example of now the decommissioned nuclear MK45 Torpedo, the US govt disclosed the exact amount in a 2023 solicitation. It describes the torpedo battery having approximately 62 lbs. of pure silver and approximately 320 lbs. of silver chloride.

Pictures of MK45 Torpedo Silver Battery

Although the Mk45 torpedo is no longer in use, over its service life, six hundred were produced and serves as a prime example of the misuse of precious silver by the military.

The USS Scorpion, lost with all hands in 1968 contained two Mk45 torpedoes; both units are presumed lost at the wreck site.

Aside from that incident, its presumed the rest were recycled or sold to allies, but the modern torpedoes have not downgraded and have maintained the use of silver batteries.

Lithium, due to the volatile nature of how it interact with water, these types of batteries are reserved only for testing torpedoes that are recovered after use.

Modern Torpedoes

Black Shark Torpedo

The Black Shark heavy weight torpedo is powered by an electrical propulsion system, which is based on a silver oxide and aluminum (Al-AgO) battery. Developed by Saft, the AgO-Al batteries are provided with high energy density and high electrolyte conductivity offering maximum safety and storage life of up to 12 years. The system delivers twice the power and energy of a standard zinc / silver oxide (Ag-Zn) battery.

Thanks to EaglePicher's disclosed details of their battery, we can make an informed estimated that the amount of silver used is between 100-150 kg.

For 100 batteries, that's around 300-500k ounces of silver!

DM2A4/SeaHake mod 4

The torpedo is equipped with a high frequency permanent magnet motor and silver zinc battery modules ensuring a maximum speed of 50kt and a range of over 50km (27nmi).

F21 Heavyweight Torpedo

The F21 can be operated in depth ranging from 10m to 500m and is driven by electric propulsion based on the silver oxide-aluminium (AgO-Al) primary battery providing a speed of 25kt to 50kt, range of over 50km and endurance of one hour.

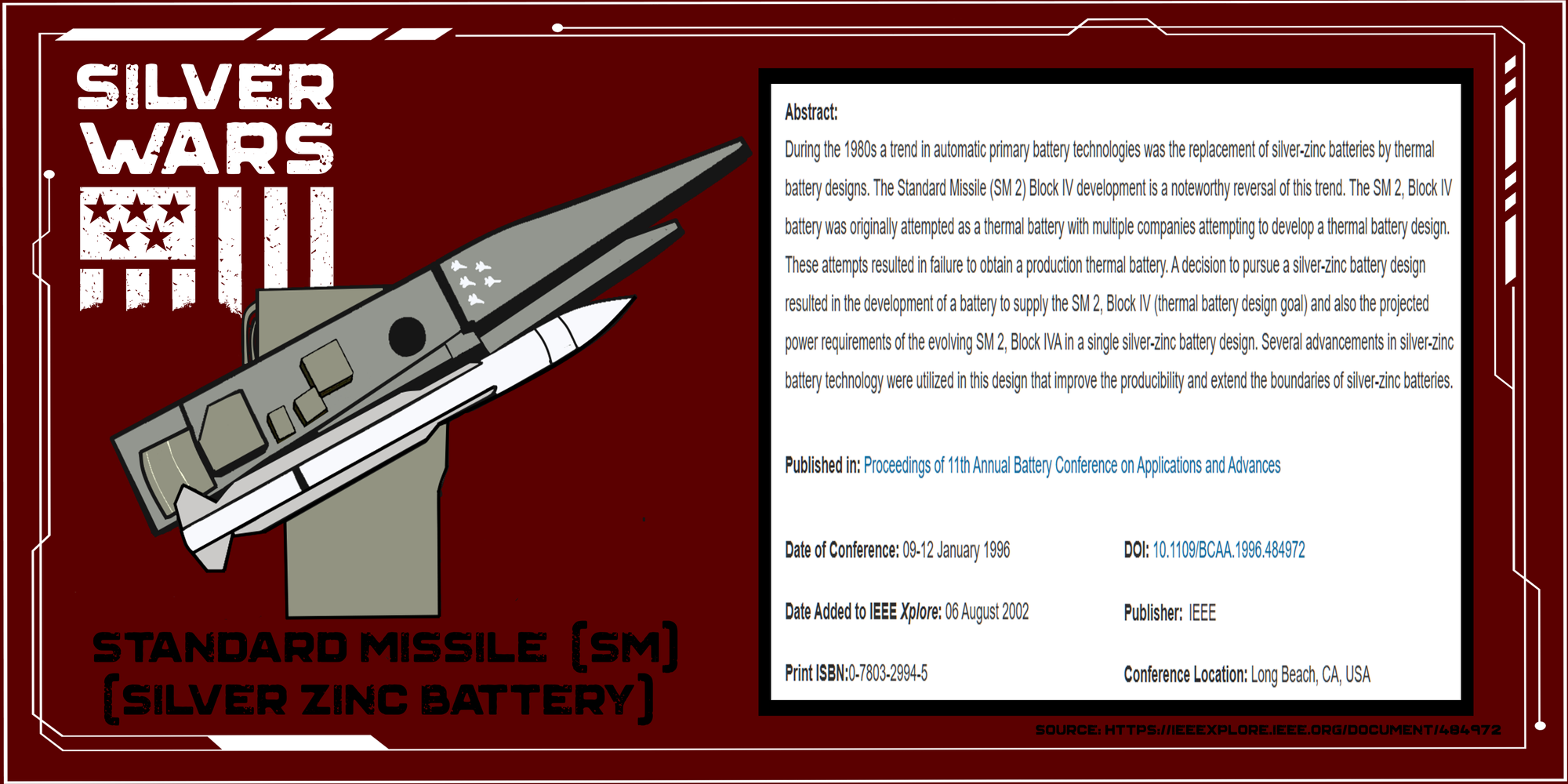

Silver is Standard for Navy Missiles

Earlier we mentioned a trend in the 1980s that saw the MIC start to replace Silver-Zinc batteries, but not all applications could be replaced. A notable reversal of the trend is the Standard-2 Missile (SM-2). All attempts to replace its battery failed because nothing could follow through with the same high power and efficiency of silver-zinc.

The Standard Missile is a medium-range surface-to-air missile (SAM), with a secondary role as an anti-ship missile, developed for the United States Navy (USN). These missiles are still in use today by the US and many NATO countries.

Over 5000 of these munitions have been produced. Many have been used.

In modern times, silver is blown up while gold sits and collects dust. Think about that the next time you see an ad for gold.

(Sources)