So here’s the thing nobody talks about when gushing over Tesla’s Optimus or some kung-fu android on TikTok: every humanoid robot is basically a walking metals depot. And not just any metals. We’re talking silver, gold, rare earths, and enough copper to wire a small apartment building. This isn’t just a tech story. It’s a resource story. And we better start treating it like one.

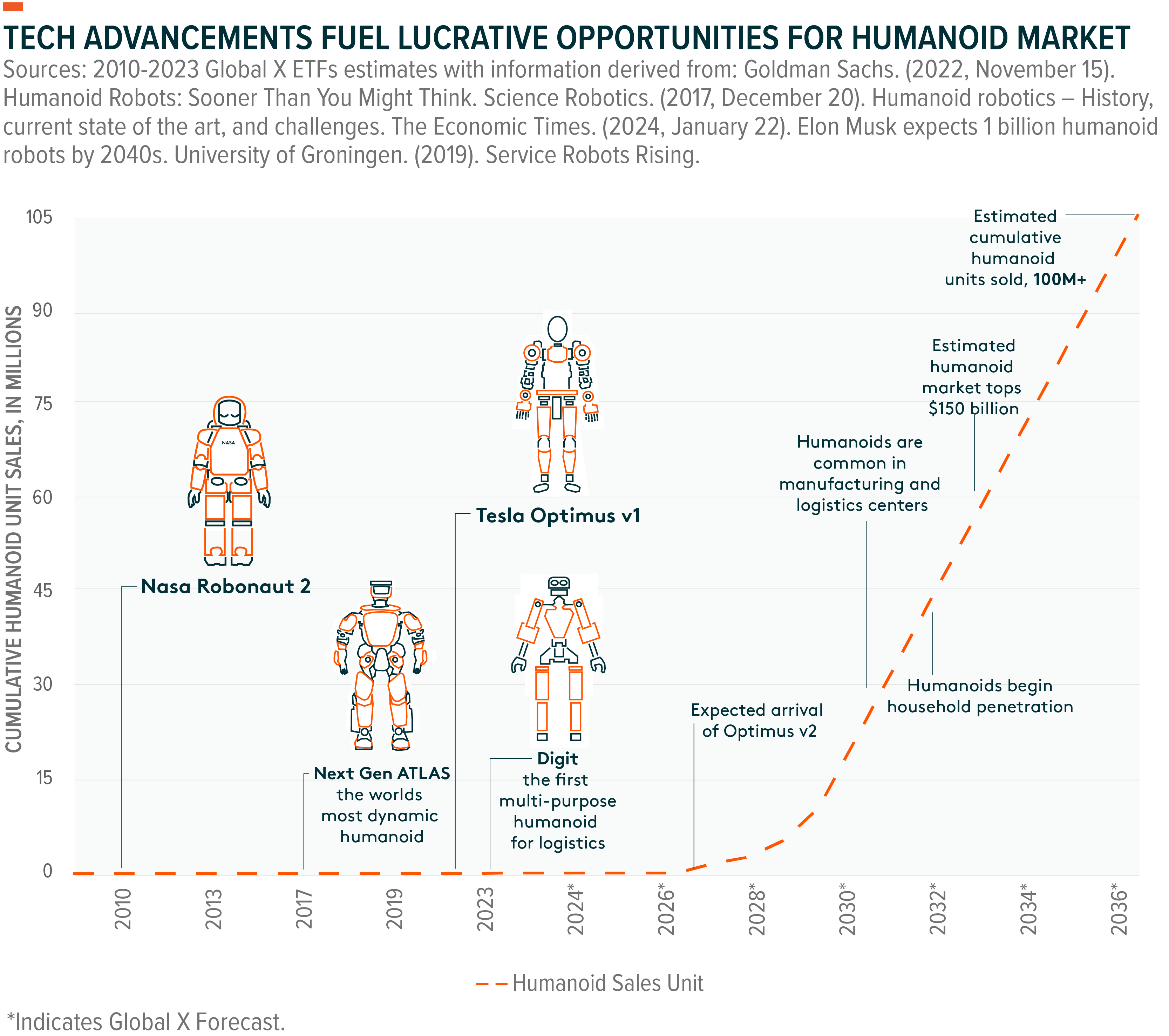

Humanoid robots are packed with joint motors, sensors, processors, power systems, and control networks. Every one of those parts pulls in critical minerals—stuff that’s expensive, increasingly scarce, and usually mined under difficult conditions. And with companies aiming to scale up humanoid robot production into the tens of thousands (and eventually millions), we’re on a crash course with some serious material bottlenecks.

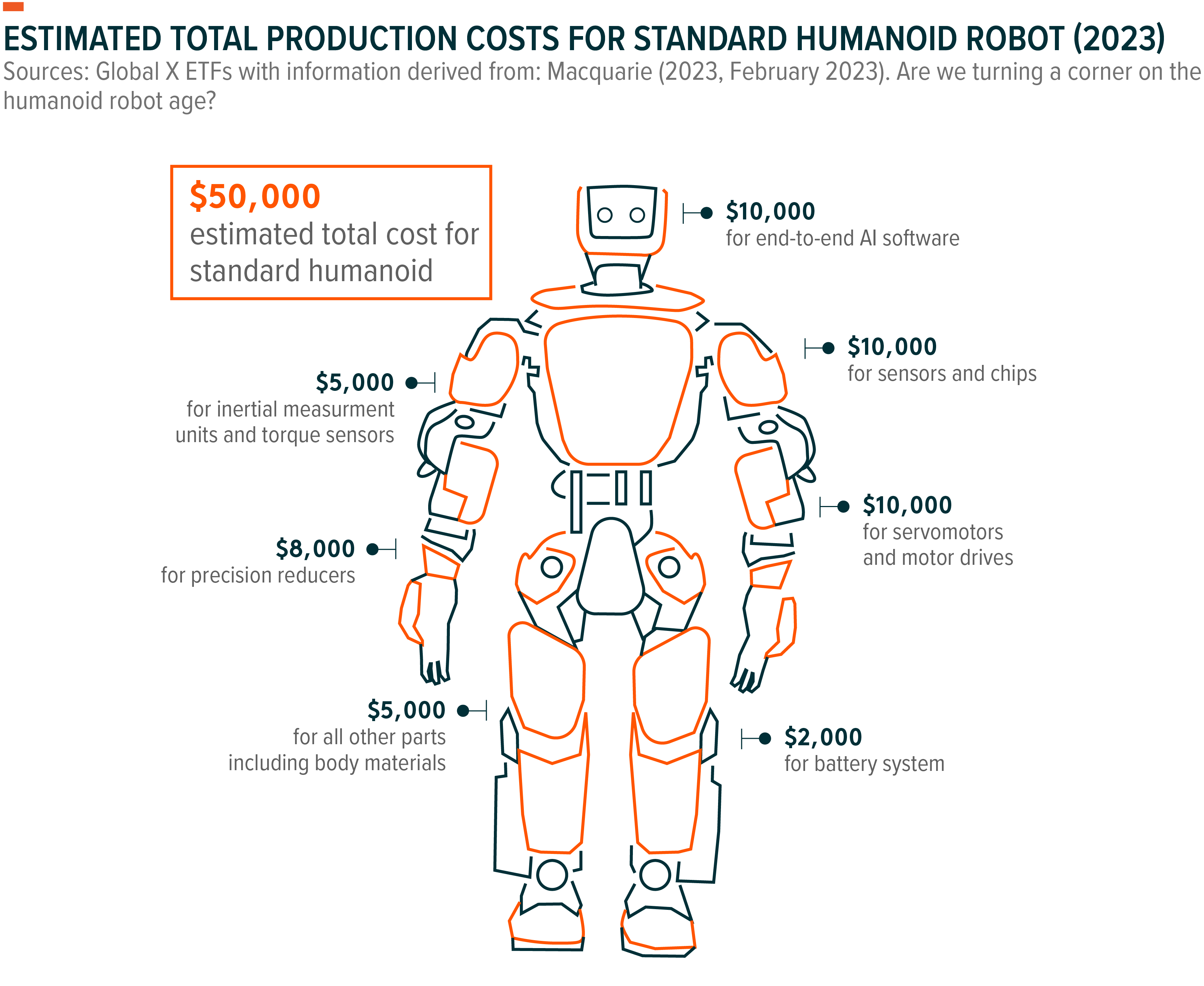

What’s Inside a Humanoid Robot

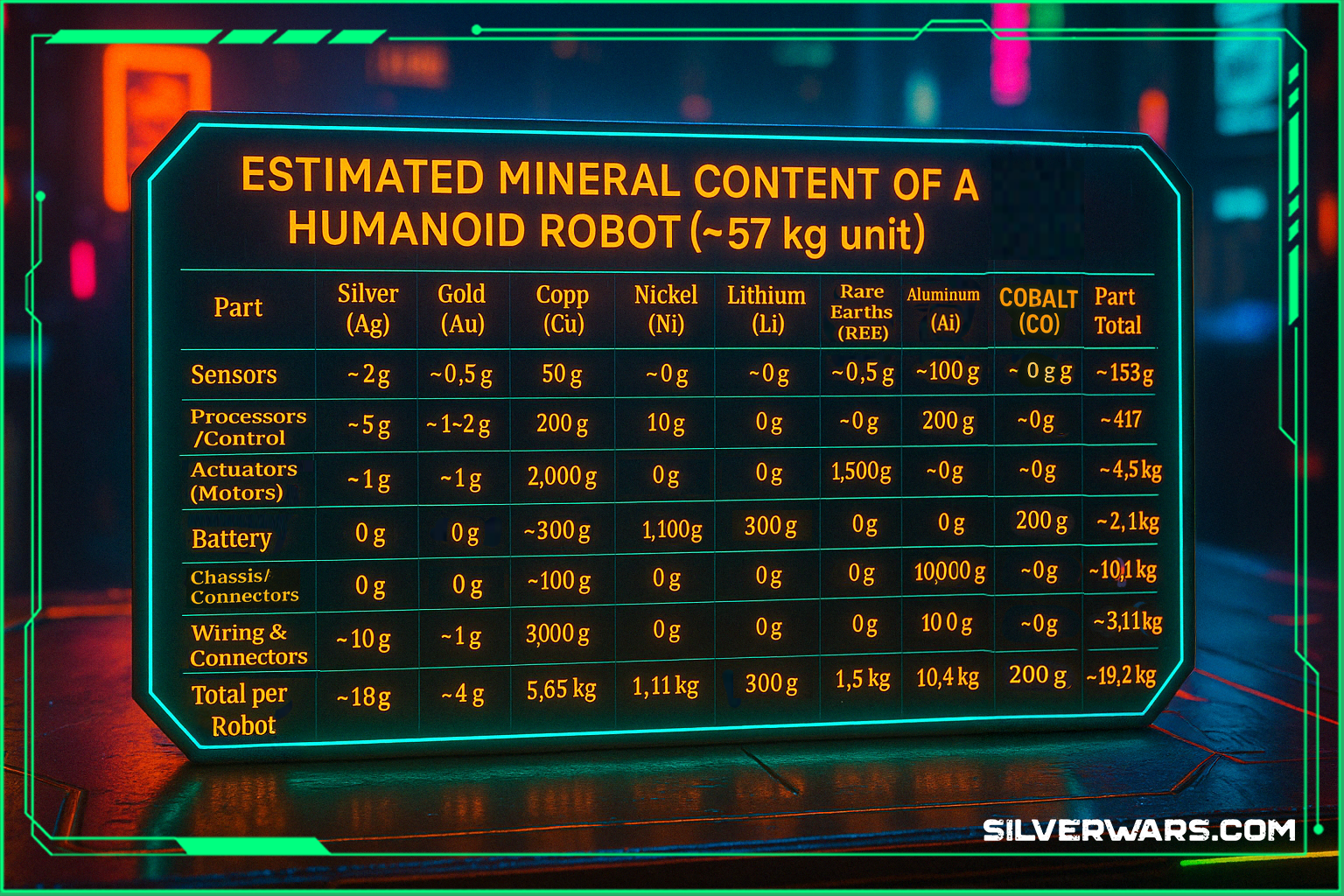

Let’s strip one down. A modern humanoid robot—say, a 57 kg unit like Tesla’s Optimus—uses a combination of lightweight aluminum chassis, lithium-ion batteries, and dozens of compact electric motors. Those motors contain rare earth magnets. The batteries pull from lithium, cobalt, and nickel. And everything else? It’s wired together with copper and soldered with silver.

Here's a mineral-by-mineral breakdown of what you’ll find in a single humanoid robot:

Estimated Mineral Content of a Humanoid Robot (~57 kg unit)

This is just the metallic stuff. Add the plastics, rubber, steel, and software infrastructure, and you’re looking at a complex, resource-heavy product. And while the aluminum and copper are recyclable and abundant (for now), the silver, rare earths, lithium, and cobalt are far more geopolitically dicey.

Silver: Small Grams, Big Impact

You might think: “Only 18 grams of silver? That’s nothing.” But multiply that by a million robots? That’s 18 metric tons of silver. And considering global industrial demand for silver is already straining supply chains—thanks to solar panels, EVs, and consumer electronics—that kind of growth curve isn’t trivial.

Silver is mostly used for solder and high-performance contacts in robot systems, such as silver nanowiring. It’s unbeatable for conductivity, which makes it a go-to material for sensors, motor terminals, battery relays, and heat-sensitive data connections.

The scary part? Silver isn’t recycled in high volumes from e-waste. It gets lost in landfills, smelted into slag, or burned off during incineration. So every robot made today is locking in silver that won’t be coming back any time soon.

Rare Earths: The Real Strategic Choke Point

Motors and sensors in humanoid robots rely heavily on NdFeB magnets—neodymium, praseodymium, dysprosium. These are rare earths sourced mostly from China, and the global supply chain is fragile at best. If you’re building a robot that needs to walk, lift, or flip, you’re using rare earths. No way around it.

Humanoid robots use less rare earths than industrial ones, but not by much. And as they scale, demand will explode. The mineral demand per unit might be a few kilos, but at 10 million units? That’s tens of thousands of tons of REEs, mostly controlled by one geopolitical rival.

Batteries: Where the Real Volume Hits

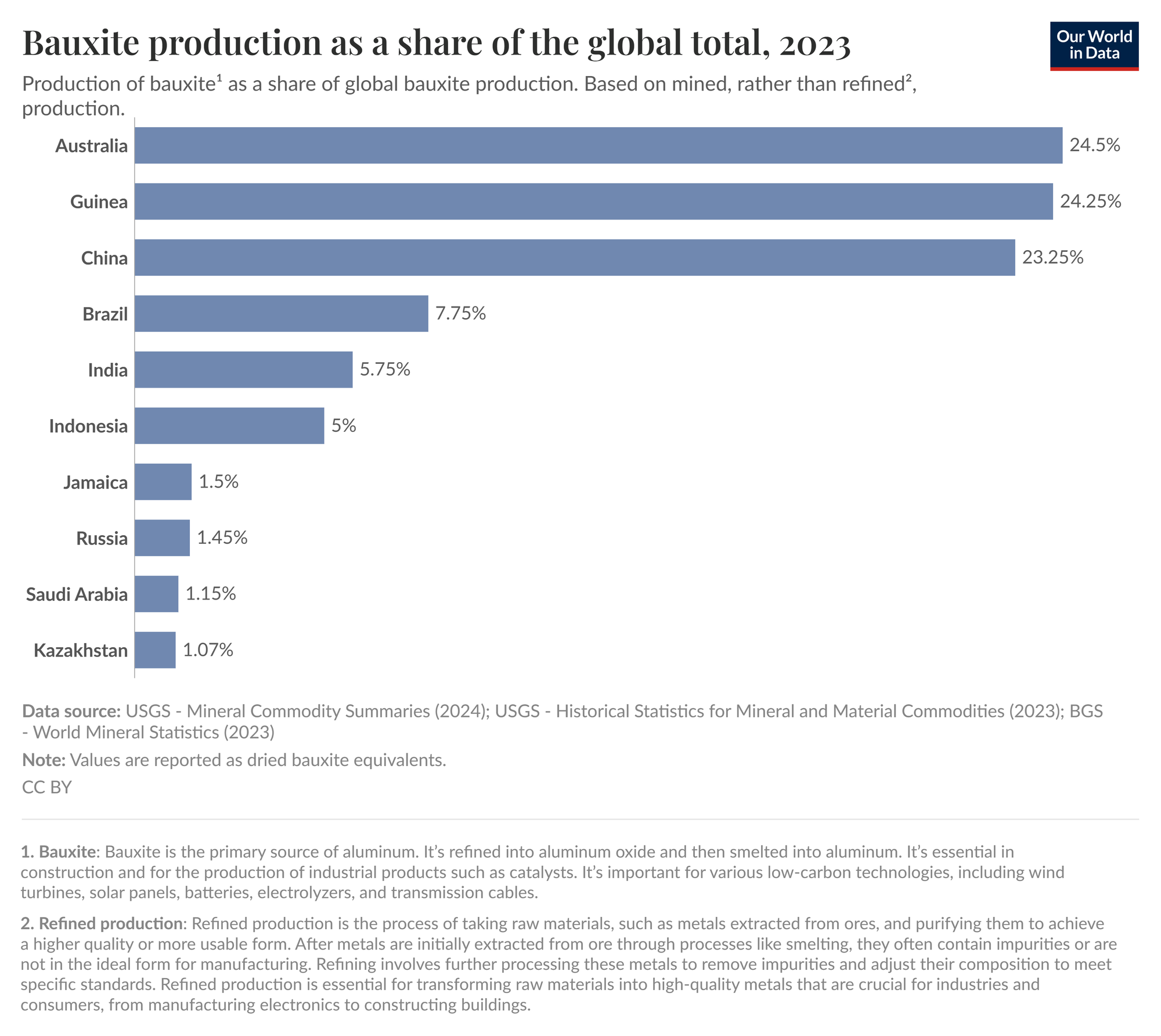

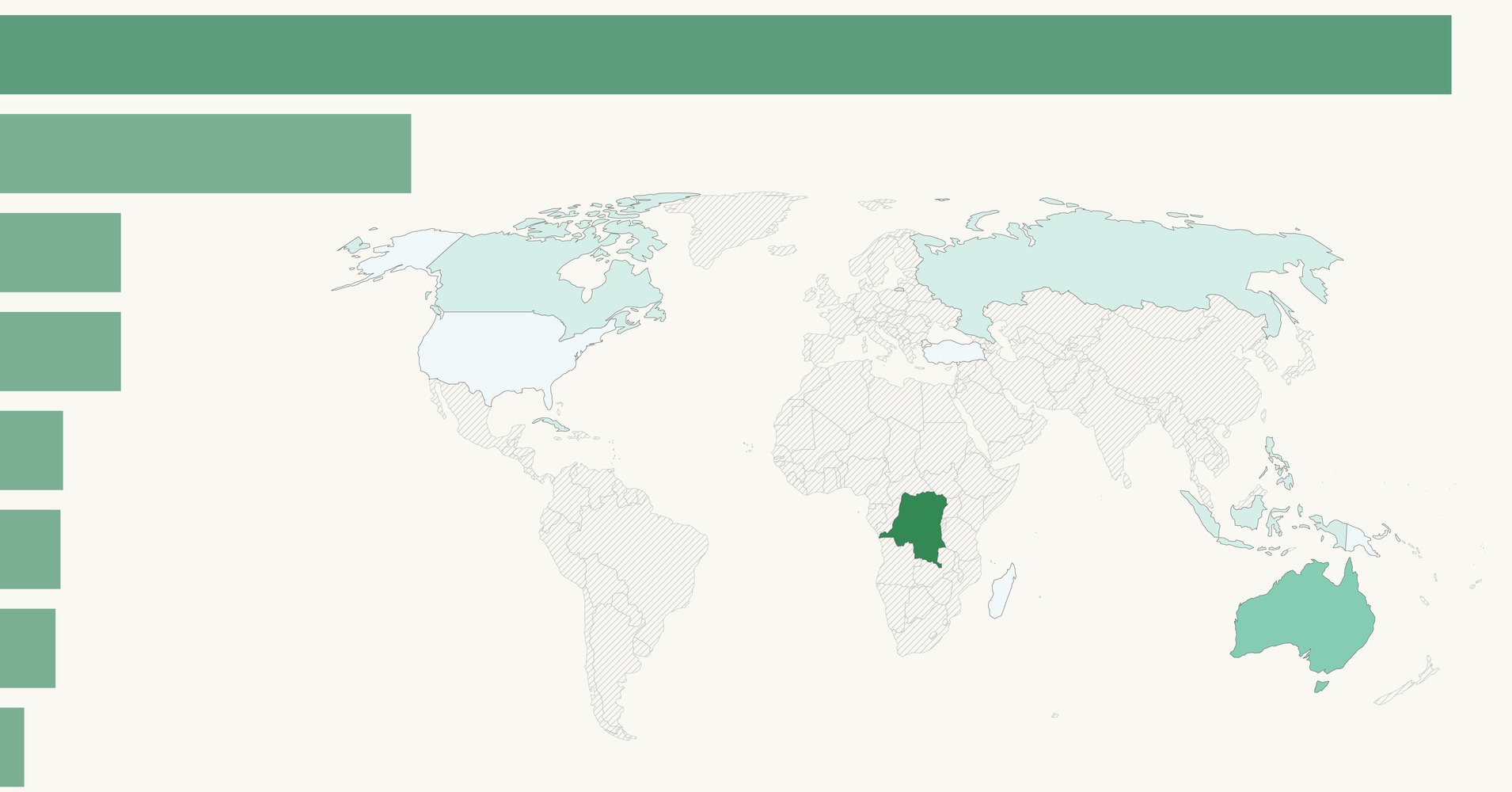

Each robot battery (say, 2.3 kWh) brings in hundreds of grams of lithium, cobalt, and nickel. These are also on critical minerals lists worldwide. Most of the world’s cobalt comes from the Democratic Republic of Congo. Lithium mining is concentrated in Chile, Argentina, and Australia. Nickel supply chains are running hot due to demand from both EVs and AI servers.

These minerals have real human and environmental costs. Water usage, pollution, and labor conditions in the Global South are a far cry from Tesla’s sleek PR campaigns. And yet, if the robot revolution comes to pass, these are the building blocks that will make it possible.

You Want AI in a Body? Better Start Digging

Everyone’s hyped about the humanoid boom. But for every viral robot backflip, there’s a kilo of copper and a few grams of rare earths that had to be mined, refined, and assembled under less-than-ideal conditions. There’s no such thing as a “clean” robot.

If we're going to build millions of these things—servants, workers, soldiers, industrial orgasm units, whatever—we better start having real conversations about where the materials are coming from, who's extracting them, and what it means when we scale intelligent machines that require non-renewable materials.

The future isn’t just made of code. It’s built on a foundation of silver, copper, and sweat. Don’t let anyone sell you the robot dream without showing you the invoice.