BYD, China's leading electric vehicle manufacturer and a formidable rival to Tesla, is constructing a colossal manufacturing complex in Zhengzhou, Henan Province. More than a conventional factory, this enormous facility resembles an industrial city, sprawling over an area equal to San Francisco. Behind this ambitious project lies a significant economic reality—the depletion of the world's limited above-ground silver reserves, exacerbated by BYD’s extensive use of robotic automation.

BYD Factory Larger than San Fransico

A Manufacturing Behemoth in the Making

BYD’s Zhengzhou factory is remarkable by any measure:

However impressive these statistics appear, it’s essential to understand the implications of such massive silver usage, especially given its finite global supply.

Robotics and the Looming Silver Shortage

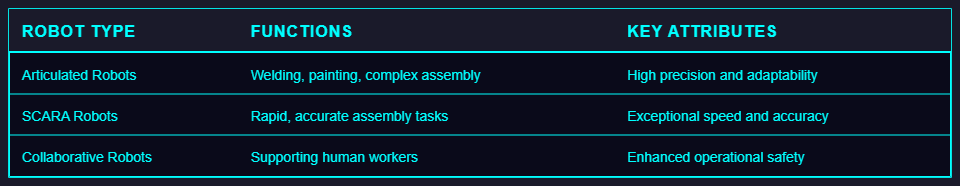

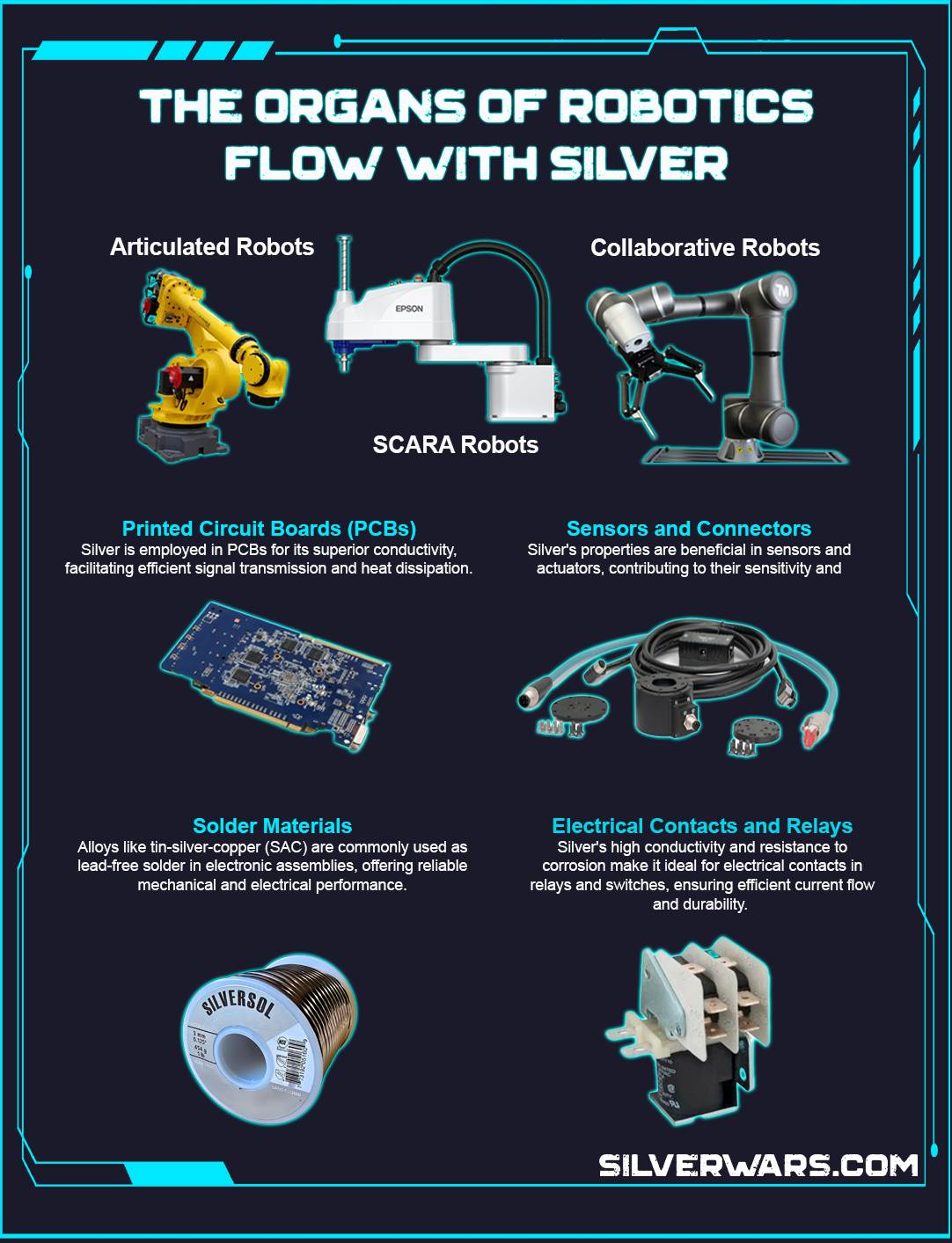

BYD’s new facility is not merely an assembly plant—it’s densely populated with advanced robotics designed for unparalleled efficiency. This robotic workforce includes Articulated Robots, SCARA Robots, and Collaborative Robots (Cobots).

Here's a snapshot of their roles:

All these robots rely significantly on silver. Every connector, circuit, and internal wiring system uses silver due to its superior electrical conductivity and reliability. The extensive network of robotic infrastructure, from charging units to sophisticated wiring, dramatically increases silver consumption.

Scara Robot Arm

The Silver Crisis: Depleting Above-Ground Reserves

Silver’s critical role extends beyond BYD, penetrating deeply into industries such as automotive manufacturing, mining, construction, and industrial automation. This shift toward widespread robotic implementation significantly accelerates silver consumption rates.

Yet BYD’s facility takes this demand to a new extreme. Tens of thousands of robotic units installed across a vast industrial area mean substantial silver consumption, posing a real threat to global above-ground silver reserves. Unlike renewable resources, silver cannot simply be replenished. The relentless industrial appetite for silver is rapidly outpacing available supply.

General Purpose Robotics and Machine Tool Loading

Rather than focusing only on price fluctuations, investors should be mindful of this severe limitation in silver availability. This scenario paints a stark picture of potential shortages, which could trigger major disruptions across multiple industries heavily reliant on silver.

Blade Battery: Amplifying Silver Consumption and Market Risks

Battery Blade Technology

BYD’s Blade Battery technology, acclaimed for improved safety, durability, and longevity, also significantly heightens silver demand. Each battery cell heavily incorporates silver in its wiring, ensuring efficient electricity transmission, thermal management, and structural integrity.

Silver’s role in the Blade Battery technology includes:

- Safety: Silver wiring ensures reduced heat generation.

- Strength: Structural integrity supported by silver connections.

- Durability: Longevity with over 5,000 cycles backed by silver reliability.

BYD Solves Tesla's Exploding Car Issue

Despite technological advancements, the aggressive use of silver presents a major economic vulnerability. Rising scarcity of silver might not only inflate manufacturing costs but could also severely constrain production capabilities, affecting market affordability and consumer accessibility to electric vehicles.

The Silver Resource Crisis Expands

BYD’s immense investment in robotics and battery technology clearly highlights the critical state of global silver resources. Investors should not merely view this project as an industrial milestone but rather as an economic warning sign indicating looming supply chain vulnerabilities due to limited silver reserves.

This facility is not just a testament to innovation; it stands as a monolith of Silver usage in the world. Investors and industry leaders must acknowledge and strategically address the harsh reality of the world's rapidly dwindling Silver supplies. But, in all honesty, it's probably to late.